Chek Lap Kok Airport

Project Overview

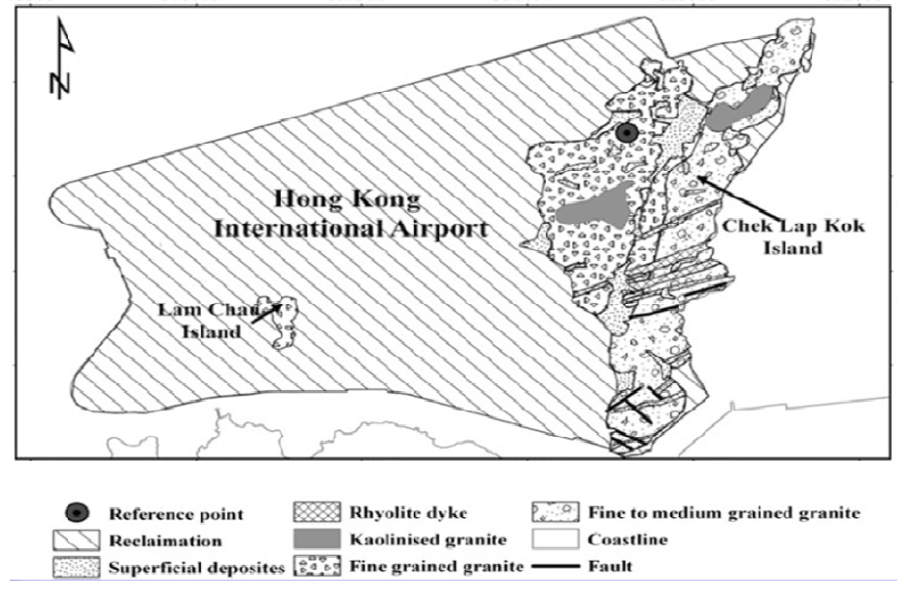

Chek Lap Kok Airport was built on an airport platform (12.5 km²) with 75% of the area on reclaimed land with the remaining 25% formed by excavating two existing granite islands. The construction comprised the placement of approximately 197 million m³, with 70 million m³ of that being hydraulically placed dredged sand fill. The placed fill thickness varied from 10 to 25m.

Landpac's Solution

Landpac employed High Energy Impact Compaction (HEIC) to optimise the soil’s engineering properties. This technique was crucial for increasing load-bearing capacity, reducing settlement potential, and ensuring overall soil stability, especially for the southern runway area where the consolidation settlement was lower than expected.

Challenges

The project faced challenges with the underlying soil, which included dredged marine sands and decomposed granite, overlying compressible in-situ marine deposits. Inadequate compaction in the reclaimed levels posed risks to the structural integrity and safety of the airport.

Application of HEIC

Runways and Taxiways: HEIC was critical in improving the subgrade conditions, enhancing soil density and strength to withstand heavy loads.

Terminal Buildings and Infrastructure: HEIC provided a stable foundation to support the terminal buildings and associated infrastructure.

Benefits

Enhanced Bearing Capacity: HEIC effectively increased the soil’s load-bearing ability, crucial for airport operations.

Reduced Settlement: Minimized potential settlement issues, ensuring operational efficiency and safety.

Improved Soil Stability: Increased shear strength of the soil, essential for the stability of the airport’s infrastructure.

Cost-Effectiveness: Accelerated the compaction process, resulting in time and cost savings.

Monitoring & Verification

To ensure compliance with compaction requirements, plate load tests were conducted. The variability of the subgrade material necessitated rigorous QA procedures, with the initial use of a 200T Porter Super Compactor for proof rolling, later replaced solely by the Impact Compactor.

Through Landpac’s expertise in HEIC, Chek Lap Kok Airport successfully addressed its soil compaction and stability challenges, laying a robust foundation for its infrastructure.

Client: Hong Kong Provisional Airport Authority

Principal Contractor: Downer-Paul Y-McAlpine JV

Ground Improvement Contractor: Landpac

Latest news

Uncontrolled vs Contaminated Fill | Why It Matters

Understand the difference between uncontrolled and contaminated fill, the risks of each, and how Landpac’s HEIC method delivers safe, stable ground.

High-Energy Impact Compaction in Australian Mining

From haul roads in WA to tailings dams in QLD, High-Energy Impact Compaction (HEIC) is reshaping ground improvement across Australia’s mining operations. Backed by Intelligent Compaction Measurement (ICM), HEIC delivers faster, deeper, and more reliable results, boosting safety, sustainability, and cost-efficiency in some of mining’s toughest conditions.

Understanding High Energy Impact Compaction (HEIC)

High Energy Impact Compaction (HEIC) revolutionises ground improvement with its ability to achieve superior soil density and stability. Unlike traditional methods, HEIC uses advanced rollers and compaction technology to penetrate deeper soil layers.