In-situ compaction refers to the improvement and stabilisation of existing base materials onsite, rather than importing external soil. This requires thorough analysis and suitable equipment to get effective results.

Some in-situ soils are too loose in their natural state to facilitate construction on the site within acceptable settlement tolerances. This is addressed by increasing the soil density with in-situ compaction of the natural ground strata to achieve the required strength and stiffness.

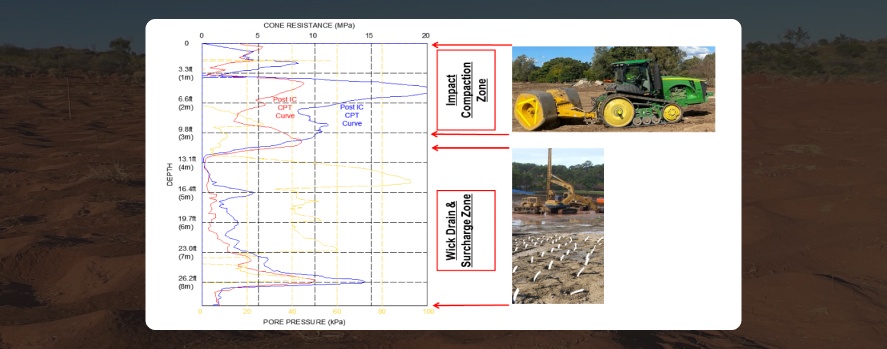

High Energy Impact Compaction (HEIC) compacts rock fills through ‘rubblisation’ of in-situ materials. In other words, breaking down large rocks into smaller particles with the use of dynamic compaction applications.

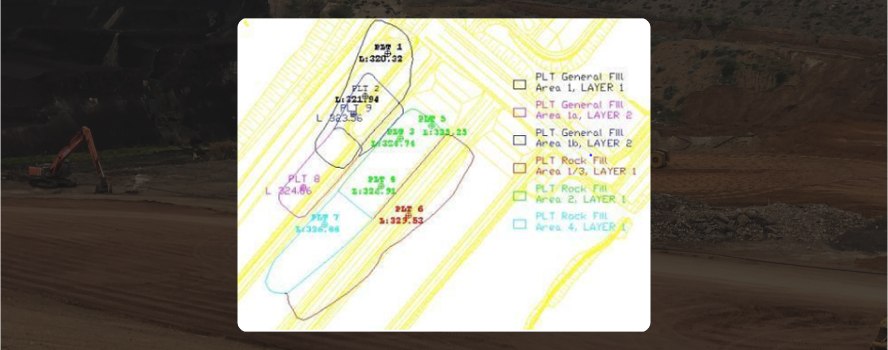

HEIC significantly benefits mixed fills in mine rehabilitation, infrastructure projects, stacker/reclaimer alignments, and mine haul roads, boosting uniformity, stability, and quality for improved construction efficiency and cost savings.

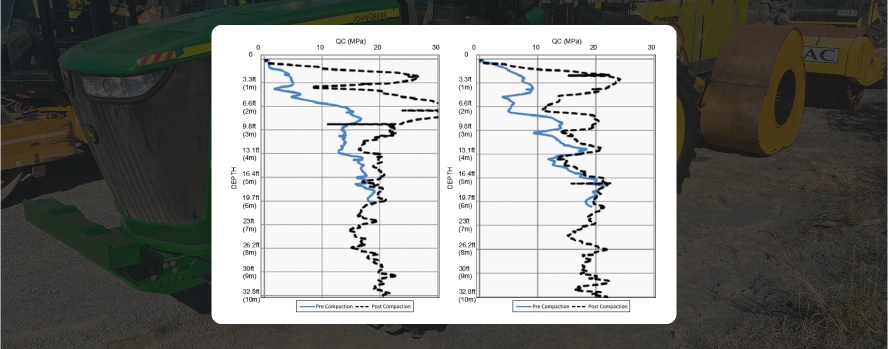

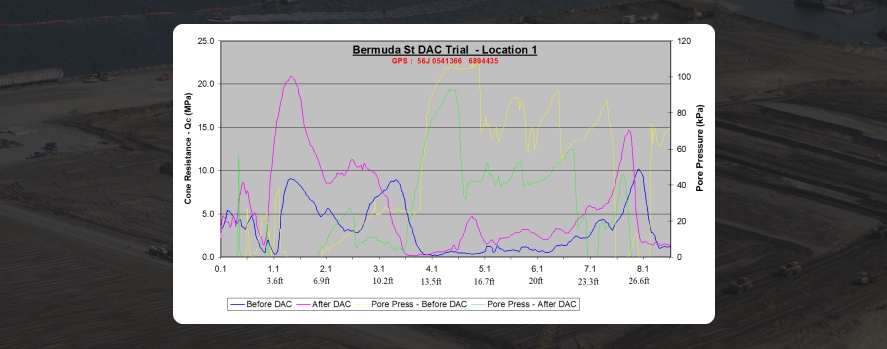

Pre and post sand reclamation CPT results to 18 feet

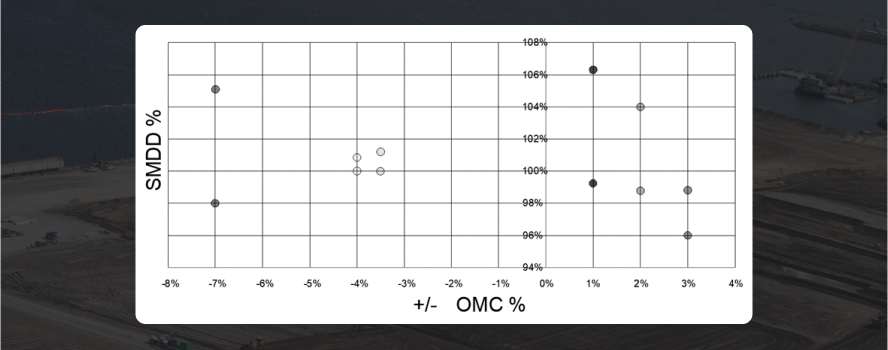

Landpac’s in-situ High Energy Impact Compaction (HEIC) offers a targeted solution to the unique challenges of sandy clay compaction in construction, significantly enhancing soil stability and load-bearing capacity directly at the construction site.

HEIC = > Elastic moduli

High Energy Impact Compaction (HEIC) provides significant benefits for saturated alluvial soils, enhancing their stability, consolidation, and overall performance.

Field trials confirmed: